The realm of materials science has witnessed a groundbreaking advancement with the development of voltage-controlled color-changing titanium. This innovative technology, which allows for precise chromatogram generation through electrical modulation, is poised to revolutionize industries ranging from aerospace to consumer electronics. Unlike traditional pigment-based coloration methods, this approach leverages the unique photonic properties of titanium oxides under electric fields, enabling dynamic and programmable color shifts with unprecedented accuracy.

At the heart of this breakthrough lies the intricate interplay between thin-film interference and electrochromic phenomena. When specific voltage gradients are applied to nanostructured titanium dioxide layers, the material's refractive index undergoes controlled alterations. These changes manipulate light absorption and reflection characteristics across the visible spectrum, producing vibrant hues that can be tuned to exact Pantone coordinates. Researchers have achieved sub-nanometer precision in controlling oxide layer thickness during the anodization process, resulting in color consistency previously unattainable in metallic surfaces.

Industrial applications are already emerging for this technology. Automotive manufacturers are prototyping self-repairing exterior paints that change color to indicate structural stress or environmental damage. The architectural sector sees potential in smart building facades that adapt their thermal properties based on sunlight exposure while maintaining aesthetic coherence with surrounding structures. Perhaps most intriguing are the military applications, where active camouflage systems can now achieve near-perfect environment matching without relying on external light sources or projection systems.

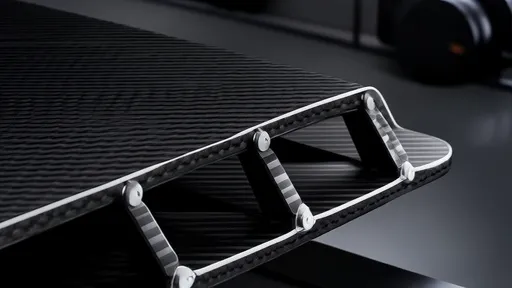

The manufacturing process involves a specialized electrochemical deposition technique that creates vertically aligned nanotube arrays on the titanium substrate. These nanotubes, typically 15-20nm in diameter, form photonic crystals whose bandgap can be electronically tuned. What sets this method apart from previous electrochromic technologies is its exceptional durability - accelerated aging tests show less than 5% chromatic deviation after 50,000 cycles, compared to conventional organic electrochromic materials that degrade significantly after just a few thousand cycles.

Energy efficiency represents another compelling advantage of voltage-controlled titanium coloration. The system requires only brief electrical pulses to maintain a specific color state, consuming mere milliwatts per square meter during static display. This makes it particularly suitable for battery-powered devices, where traditional display technologies would impose significant power burdens. Early adopters in the wearable technology sector report 30-40% improvements in battery life when replacing OLED displays with this reflective technology.

Challenges remain in scaling production to meet industrial demands. Current fabrication methods allow for about 2 square meters of treated surface per hour in laboratory conditions, though pilot production facilities aim to increase this twentyfold within two years. Another hurdle involves achieving uniform coloration across large, curved surfaces - a requirement for many automotive and architectural applications. Researchers are developing multi-electrode control systems that can compensate for surface geometry variations in real-time.

The scientific community anticipates broader implications beyond visual applications. The same principles governing voltage-controlled coloration may lead to advancements in optical computing and quantum communication devices. By precisely manipulating photon-electron interactions at the nanoscale, these titanium oxide structures could enable new paradigms in photonic information processing. Several research groups are already exploring spin-dependent electron transport through colored titanium oxide layers as a potential pathway toward room-temperature quantum computing.

Consumer electronics companies are particularly excited about the technology's potential to eliminate the trade-off between durability and display quality. Current smartphone screens, for instance, require protective layers that often degrade touch sensitivity or optical clarity. Voltage-colored titanium surfaces offer the hardness of grade 5 titanium (comparable to hardened steel) while maintaining vibrant, adjustable displays that are readable in direct sunlight. Prototype devices demonstrate remarkable resistance to scratches and impacts that would shatter conventional glass displays.

Environmental considerations further bolster the case for this technology. The anodization process uses water-based electrolytes and produces minimal hazardous byproducts compared to traditional coloration methods involving heavy metals or volatile organic compounds. Moreover, the longevity of the colored surfaces reduces material waste - a single titanium component could theoretically change its appearance indefinitely rather than requiring replacement for aesthetic updates.

As research progresses, we're seeing unexpected applications emerge in biomedical fields. The color-changing properties correlate with surface energy modifications that affect protein adsorption characteristics. This has led to prototype medical implants that can visually indicate infection or improper healing through localized color changes while simultaneously altering surface properties to encourage tissue integration. Such dual-function capabilities were unimaginable with previous generation biomaterials.

The commercial rollout of voltage-controlled color titanium faces typical new material challenges - establishing supply chains, developing application-specific standards, and educating designers about the technology's capabilities and limitations. However, with major material science conferences dedicating entire sessions to the topic and venture capital flowing into startups commercializing various aspects of the technology, voltage-controlled coloration appears destined to transition from laboratory curiosity to industrial mainstay within this decade.

Looking ahead, the convergence of this technology with other advanced materials could yield even more remarkable results. Preliminary experiments combining voltage-colored titanium with shape-memory alloys have produced surfaces that can change both color and texture in response to electrical stimuli. Such developments hint at a future where material surfaces become truly dynamic interfaces, capable of complex, environment-responsive behaviors that blur the line between inanimate objects and adaptive systems.

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025

By /Aug 19, 2025